Author: ЯНОВ ИЛЬЯ ВЛАДИМИРОВИЧ / YANOV ILYA VLADIMIROVICH

introduction

This competitive work is an intermediate result of research conducted by our team since 2016 and dedicated to the development of structures and methods for the construction of protective structures of habitable stations on the surface of the Moon and other space objects covered with regolith. Since 2017, the results of our work have been presented at Scientific Readings dedicated to the memory of K.E. Tsiolkovsky, held in Kaluga and at the XLV Academic Readings on Cosmonautics in Moscow. In 2021, our work was presented as a competitive project at the Horizon -2100 competition.

The idea of using the Moon as a raw material base of the Earth's civilization was put forward in the works of K.E. Tsiolkovsky, as mentioned in his book by V.V. Shevchenko, head of the Department of Lunar and Planetary Research at the P.K. Sternberg State Astronomical Institute of Moscow State University in [1].

The exploration of the Moon and other space objects of the Solar System, as shown by the experience of the development of hard-to-reach territories on Earth, will begin with the construction of habitable stations. The example of the study of the continent of Antarctica is particularly vivid, the temperature values of which in winter are close to lunar [2] and can drop to almost – 100 oC" [3]. Back in the first half of the last century, this southern continent was similar to the Moon in terms of its unexplored and inaccessible nature. The famous American polar explorer Richard Baird, in 1929 He said that "Antarctica is less known to mankind than the side of the Moon facing the Earth" [4]. However, after the International Geophysical Year (IGY) was proposed in the early 1950s, 9 Soviet and more than 30 foreign permanent inhabited stations were built and operated on the territory of Antarctica in 1956-1959 [2]. After that, a large-scale exploration of the mainland began. The first (temporary) structures of inhabited stations in Antarctica were prefabricated-panel and frame-panel with a steel frame and special thermal insulation, which were delivered on tractor sleds from the coast inland. Subsequently, they were replaced by modular houses made of aluminum panels with thermal insulation.

We believe that the experience of exploration of the Arctic and Antarctica can be successfully used in the process of colonization of the Moon and other space objects, and the territory of Antarctica, with its extreme climate, can become a testing ground for testing various design solutions of lunar habitable stations. Therefore, it is quite logical that at the third stage of lunar exploration in the Russian lunar program [5], it was planned to land a man on the Moon and create a permanent base there in order to begin industrial development of the Earth's natural satellite. During a press conference on September 21, 2021, the President of the Russian Academy of Sciences Alexander Sergeev, emphasizing the priority and importance of the development of a natural satellite of the Earth, added that "deep space exploration is impossible without the development of the Moon" [6]. We believe that the construction of a long-term habitable station on the Moon for its further exploration will be a phenomenon of the same order as the mastered Moon for the exploration of deep space objects.

The stages of lunar exploration proposed by specialists are given in the book [7]. In their opinion, the exploration of the Moon will begin with the creation of a temporary lunar base, which "... will provide accommodation for astronauts on the Moon for a month." Igor Mitrofanov, head of the Department of the Space Research Institute of the Russian Academy of Sciences, called the temporary base "an outpost of Russia" on the Moon, "a construction hut" for visiting expeditions" [8].

The authors of the book [7] called this stage of the construction of a habitable lunar base zero. Without such a temporary station, as they believe, it will be impossible to organize and carry out not only preparatory activities, but also the construction of a permanent habitable base on the Moon. At the second stage, a long-term lunar base will be created, which will be a large-scale development of the base of the first stage [7].

The first projects of habitable lunar planets are described in sufficient detail in the book of astronomer V.V. Shevchenko [1]. The projects considered various options for lunar dwellings and their location on the Moon, for example, in natural cavities, but mostly they were time-consuming and time-consuming to implement. The most rational solution of those projects that have come down to our days is the use of the protective properties of the lunar substance. In the future, projects of lunar bases based on ready-made modules delivered from Earth began to appear, for example, the city "Barmingrad", "Luna - 7" of the company "Lin Industrial" and others [9, 10, 11]. However, the high cost of the projects and the insufficient capacity of the launch vehicles did not allow these projects to be implemented. The protection of the modules in most projects consisted in filling them with lunar soil (the Barmingrad project), but in the Luna-7 project they were covered with a platform on which a protective layer of lunar soil was placed, which is also a more rational solution used now.

Later, projects of lunar bases began to appear after the construction of powerful launch vehicles: in the USA, the Apollo program, and in the USSR - after the Moon flyby [12].

Currently, the generally accepted concept of the design and method of erecting protective structures of habitable stations of the zero and first stages of colonization of the Moon and other natural space objects covered with regolith is their maximum protection from environmental influences, primarily from cosmic radiation and meteorites, the use of local energy sources and materials, ease of construction, gas tightness and the use of elements of special space techniques [13].

However, an equally important feature of the proposed methods of constructing habitable bases on the Moon of the last decade, as astronomer Leonov V.A. [14] put it, is the principle of robotic station construction: astronauts arriving on the Moon are settled in ready-made and fully adapted to life working modules and the construction of monolithic structures using 3D printing. An example of such a structure on the Moon, erected from hexagonal structures by the method of melting regolith using solar energy, is the lunar base called PLUS (Permanent LUnar Station), proposed by employees of INASAN, MArhI, Moscow and Samara Polytechnic Institutes, S.A. Lavochkin NGO and IPCON RAS [15].

In addition to the use of a solar 3D printer for the construction of lunar stations, other technologies have been proposed to date, some of which were cited in the article of Russian scientists [16] such as: bulk structures in the form of "bags" with regolith, synthesis of building blocks from regolith by the method of self-propagating high-temperature synthesis (SHS) technology, selective laser sintering and combination of the listed technologies.

It is also worth noting the idea of the International Design Agency A-ETS, which proposed a method for building the SinterHab lunar base, consisting of several parts resembling bubbles, protected by a layer of material created from regolith. The walls of the lunar station proposed by the agency are being built by a mobile 3D printer with a microwave heater. However, the methods of using regolith in the construction of the station using 3D printers and SHS technologies require careful preparation of the lunar soil - grinding and fractionation, which is associated with the pouring of regolith at a certain speed in 3D printers or careful preparation of a pyrotechnic mixture of regolith with fuel (SHS processes). Now, in the conditions of the Moon, such preparation is difficult to implement and requires a long time. This is caused not only by the low gravity on the moon, but also by the high "stickiness" and "stickiness" of the regolith [17]. Perhaps in the future these methods of using regolith will be in demand. But, in our opinion, the most important aspect of this method is an attempt to use a unique feature of regolith, consisting in the presence of iron nanoparticles in it, which greatly facilitates the melting and sintering of lunar soil in microwave ovens. This assumption was confirmed by our study on sintering samples from a basalt regolith simulator in a microwave oven [18].

More suitable and simple, in our opinion, is the method of construction of the station, given by astronomer V.V. Shevchenko in [1], which consists in the use of load-bearing structures that are not only building elements, but also protective. The method of construction of such station structures is based on the use of pre-prepared "formwork" filled with compacted regolith or filled with their regolith during the assembly of structures.

Analysis of existing structures of inhabited stations on the Moon and methods of their construction has shown that the most effective design of a lunar inhabited station, including a temporary one, is a structure in which the supporting building element performs the function of protecting the station from the dangers of the Lunar space environment [1], and the most effective way of using regolith is a method that does not requiring a long and thorough preparation of the lunar soil.

In this regard, the relevance of our project, as we believe, is beyond doubt, since we offer a well-founded and simple design and method of erecting a pre-erected protective structure (BZS) of a habitable station on the surface of the Moon, in which the protective structure is both a load-bearing building element, and the use of regolith as a construction and protective the material during the construction of the structure does not require a long and thorough preparation of the lunar soil. The simplicity of the design of our BZS will allow in the future to robotize the entire process of its construction.

Since there are natural space objects of the Solar System in the Solar System - atmosphere-free planets, Mars, the Moon and some asteroids and satellites of planets whose surface is covered with regolith with a similar composition to the lunar one, it is quite possible to use our design for the temporary stay of astronauts on these objects, of course, taking into account the specifics of the place of stay [19].

Objective: to develop the design of the BZS of a temporary habitable station on the Moon using regolith and a sufficiently simple method of its construction, allowing this method to be further robotized and used for the construction of BZS on other space objects covered with soil, the composition of which is similar to the lunar composition.

Tasks:

- development of the basic design and method of erecting protective structures of a temporary habitable station on a pneumatic deck using a local regolith material in a recess on the surface of the Moon;

- development of the design of folding building elements of the frame-filling structure of the inhabited station, filled with regolith, without its special preparation;

- development of a method to increase the radioprotective ability of the bearing parts of the building elements of the backfill frame;

- development of the design and method of erecting a frame-backfill protective structure of a temporary habitable station, using regolith that does not require special long-term preparation and taking into account its further robotization.

The novelty of the project

- for the first time, the basic design of the protective structures of a habitable station on the surface of the Moon was developed, based on the use of various technologies for the construction of structures, including the use of a design of folding compact buildings of building blocks and a method for its construction on a pneumatic formwork using regolith in a recess on the surface of the Moon. An application for invention No. 2022116899 has been submitted for the basic design of protective structures and the method of its construction;

- for the first time, a successful experimental evaluation of the possibility of activating the process of manufacturing a radioprotective composition based on barium sulfate and liquid glass in a microwave oven was carried out;

- for the first time, designs of folding elements of the BZS frame of a temporary habitable station of increased radio protection have been developed;

- for the first time, a new type of construction of a manned station based on a frame-filling formwork and a method for its construction on the surface of the Moon and other space objects has been developed.

the main part

Results and their discussion

1. Development of the basic design of the BZS of a temporary habitable station on the surface of the Moon and other space objects of the Solar system covered with regolith, the composition of which is similar to the lunar

September 7, 2017 marked the 160th anniversary of the birth of the founder of cosmonautics K. E. Tsiolkovsky (1857-1935), and on September 20, 2017 in Kaluga, our team presented at the 52 Scientific Readings in memory of K.E. Tsiolkovsky in Kaluga the first results of research on the design and method of constructing a habitable base on the surface of the Moon, which we conducted as part of regional school competition "Take-off 2016-2017".

In the course of the competitive work "Take-off 2016-2017", and then in 2018 and 2020, we proposed lancet and then conical domes, erected using pneumatic formwork in a recess on the surface of the Earth satellite from separate regolith blocks sintered in a microwave oven, as BZS of temporary inhabited stations on the Moon.

The results obtained were presented in a competitive paper at the Horizon 2100, 21 competition [20] and in reports at the 56th and 57th Scientific Readings in memory of K.E. Tsiolkovsky in Kaluga [19, 21].

1.1 Basic design of the BZS temporary habitable station on the surface of the Moon

In this paper, based on the generalization of the results of our research, we present the basic design of a temporary habitable station and the method of its construction in a natural depression on the surface of the Moon. The device of the basic design of the BSZ is shown in Fig. 1.

Fig. 1. – A habitable station on the Moon based on the basic design of the BSZ:

1-an anti-meteorite layer; 2-an anti-radiation layer; 3- a conical coating; 4- a wall of a natural recess on the surface of the Moon; 5- a cylindrical part of the structure; 6-a pneumatic formwork; 7- a residential module; 8-an airlock; 9- a hatch for access to the surface of the Moon; 10-a recess wall; 11- sealing device for sealing the entry point of the airlock chamber into the cylindrical part of the BZS

The basic design of the BZS is a domed structure consisting of two parts – a lower, cylindrical wall structure that performs the function of a support ring and an upper, conical dome, which is the covering of the structure.

The basic design of the BZS is composed of trapezoidal regolith blocks (or hulls) with the help of a pneumatic formwork in a recess on the surface of the Moon. Regolith blocks can be made by various existing methods and must contain locking elements for their fastening.

The pneumatic formwork is used not only for a simpler and more accurate construction of a protective structure, but also for sealing the internal volume of the BZS and consists of two hermetically connected sections, the upper of which is used for the construction of a dome conical coating and a cylindrical part of the supporting structure, and the second section is its base, laid on the construction site. The section of the airlock chamber passing through the wall of the cylindrical structure is reinforced from the outside with a coil-shaped ring made of composite material. The protective coating of regolith that covers the structure consists of an anti-meteorite layer of regolith blocks or is made using a solar concentrator by melting a regolith layer with a thickness of at least 0.1 m. The anti-meteorite layer of solid regolith is laid on an anti-radiation layer of bulk regolith with a thickness of 1 to 3 m, moreover, the protective coating is laid with an emphasis on the walls of the recess.

The surface of the territory measuring 90 × 90 m, from which a layer of loose regolith was removed for the construction of the station, is melted by a solar concentrator and used as a spaceport.

According to the latest calculations of scientists based on the results obtained by the Chinese spacecraft Chang'e-4, the protective anti-radiation layer of the regolith may be about 0.76 m [22]. Under such conditions, the radiation level will be approximately equal to that of Earth.

Taking into account the analysis of the literature, the results of previous studies and the latest results obtained by the Chinese spacecraft Chang'e-4, as well as the goals and objectives set, the following working hypothesis was formulated:

it is assumed that if we develop a design of folding building elements (SE) for the construction of a strong hollow frame around a pneumatic formwork, previously developed by us for the construction of the basic structure of the protective structures of a habitable station on the surface of the Moon [23], moreover, these elements should be manufactured in advance, giving them some additional radioprotective ability and delivering them to the construction site in folded the construction of the protective structure will take place without a long process of manufacturing regolith blocks, and it will consist in the construction of the frame and its filling with regolith without long-term preliminary preparation of the lunar soil (grinding, fractionation), therefore, such a structure will be pre-erected and can be erected on all natural objects of the Solar System containing regolith as a manned station for the safe residence of astronauts during the entire time of preparatory activities and subsequent construction of a permanent habitable bases on these objects.

2. Development of the design and method of construction of a frame-backfill BZS of a temporary inhabited station

In this competitive work, we propose a new solution to the method of using regolith on the Moon during the construction of a habitable station, once proposed by astronomer Shevchenko V.V. in [1] and consisting in the fact that "A pre-prepared formwork can be filled with regolith and compacted with any of the mechanical devices." We propose to build the volumetric "formwork" mentioned by V.V. Shevchenko in the form of a volumetric frame of individual SE around the pneumatic formwork, then fill it with bulk regolith and seal or seal it in the process of filling with regolith. Frame-backfill technology will not only reduce the cost of the construction of the protective structure of the inhabited station and simplify the process of its construction, but also increase its radio protection, by giving a similar ability to the walls of building elements.

2.1 Development of the frame-filling structure of the BZS

As already mentioned, the first structures at polar stations in Antarctica were temporary prefabricated panel and frame-panel houses with a steel frame and with special thermal insulation. [2]. However, the very first frame structures used in the northern polar latitudes were KAPSH tents, the design of which was once proposed by S.A. Shaposhnikov for an expedition that drifted on the ice in 1937 [24]. The tents had a hemispherical frame made of duralumin arcs with a two-layer fabric covering.

According to the information given in the builder's handbook [25], wooden walls of buildings are divided into frame (frame-backfill, frame-shield, shield), log and bar walls. Moreover, frame-backfill walls are used in the construction of temporary structures, such as suburban buildings [25]. But time has shown that all types of frame houses can be equally in demand, since the advantages of these houses are the speed of construction and low cost [26].

In accordance with modern technologies, a frame house is a frame sheathed with external and internal insulation panels, between which there is either a shield or bulk insulation [27].

To reduce the cost of the construction of the BZS of the inhabited station on the Moon and simplify the method of its construction, we proposed to use simpler folding construction elements instead of separate collapsible buildings filled with regolith, from which it will be possible, using pneumatic formwork, to erect the inner and outer walls (sheathing) of the frame of the protective structure, after which the gap between them should be filled with bulk or compacted regolith. In this case, the frame covered with regolith will be a single monolithic structure made of compacted regolith, in which there are no joints and walls between any individual elements of the structure. In this frame, regolith serves not only as a protective and building material, but also as a bulk insulation - "an excellent heat insulator", as it was said in [17].

2.1.1 The design of folding building elements of the frame-backfill BZS station and the method of their fastening

For the frame of the BZS, the designs of individual SE conical and cylindrical parts of the structure were developed. The designs of the developed BZS folding housings were taken as the basis of the SE [19].

The proposed SE for the construction of walls (internal and external) of the frame are products consisting of two wall panels (external and internal) connected by a jumper that is pivotally attached to them. This structure can be folded and rigidly fixed in the unfolded (working) state.

With the help of a pneumatic formwork from these SE, two walls of the BZS frame are simultaneously erected. SE are connected to each other butt-to-butt with their wall panels using lock connections. An example of such a connection is the locking connection of laminate elements (flooring) of the type of latch locks (Lock system) [28], which is now used almost all over the planet. The connection of plastic parts in this way, as follows from the book [29] "is very simple, fast and economical." In addition, such locking connections make it possible to perform multiple docking and undocking of the SE [29], which allows, if necessary, to disassemble the protective structure and move it to another place.

1.1.2 Increasing the radio-protected ability of the walls of building elements

As a material for the manufacture of SE, we proposed using a carbon fiber composite. Low density, high strength and heat resistance (up to 400 OC) allows this material to be used in the aerospace industry [30]. In order to give carbon fiber an additional ability to radiation protection, we proposed using a composition of liquid glass (an aqueous solution of sodium hydrosilicate) and barium sulfate in its manufacture. Similar compositions are used in radioprotective concretes, where liquid glass is used as a binder, and barite, a natural mineral containing more than 94% barium sulfate, is used as a radioprotective filler and hardener of liquid glass [31]. Such a composition can also be applied to the surface of carbon fiber plates, since it is known that liquid glass materials have sufficiently high adhesive properties [32].

In addition, barium salts are also effective hardeners of sodium and potassium hydrosilicates [32]. The choice of barium sulfate was due to the fact that it is not soluble in water, therefore it is non-toxic and does not pose a threat when used, unlike, for example, soluble barium salts, the lethal dose of which is 1 g [33].

In order to assess the possibility of manufacturing a dense and durable X-ray protective material from a liquid-glass barium composition, studies were conducted. Two series of samples were made from finely dispersed barium sulfate and liquid glass, after which the samples of the first series were dried in a drying cabinet, and the samples of the second series were exposed to microwave radiation in a microwave oven. After manufacturing, the samples were subjected to compressive strength tests.

It turned out that with the same density of the samples obtained, the processing of prototypes in a microwave oven led to an increase in their compressive strength by almost 70%, with significantly less processing time in a microwave oven (18 times).

The fact of a significant increase in strength and a decrease in the processing time of samples in a microwave oven can be explained, as well as possibly by a higher temperature during processing in a microwave oven, and by a more complete and rapid course of solid-phase reactions in samples activated by microwave radiation with the formation of silicates and barium hydrosilicates [34, 35], which have a high binding capacity [36].

Since X-ray radiation refers to ionizing radiation similar to gamma radiation [37], we evaluated the ability of the experimental material to protect against cosmic radiation by its ability to protect against X-rays.

Therefore, an estimated comparative calculation of the X-ray protective ability of the experimental material and various modern protective X-ray protective building materials was carried out further. For comparison, barite plaster [38], Knauf-Safeboard plate (Germany) based on barium sulfate [39] and experimental material based on barium sulfate and liquid glass (excluding the contribution of sodium hydrosilicate) were used.

A comparison of the X-ray shielding ability of the materials showed that when using an experimental composite, the X-ray shielding ability of the frame will increase by the amount of the radioprotective ability possessed by a 0.4 mm thick layer of lead.

Thus, the conducted studies have shown the possibility of using a composition of barium sulfate with liquid glass as a binder in the manufacture of carbon fiber - a durable material that helps to increase the radioprotective ability of the BZS station frame.

2.2 Design and method of construction of the frame-backfill BZS station on the surface of the Moon

2.2.1 Construction of the frame-backfill BZS of the station

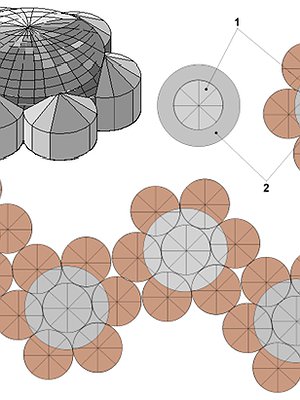

The structure of the frame-filling BZS of the station of the minimum configuration is shown in Fig. 2.

Fig. 2. The design of the BZS of the inhabited station based on the frame-filling structure:

(the explanatory text is given in the appendix of the work)

The structure of the frame-filling BZS consists of separate SE forming a volumetric frame consisting of a lower cylindrical part (14) and an upper conical coating (3). The SE of these parts differ in their design.

A residential module (10) is installed inside the BZS in factory readiness for astronauts to live, and their life support system is installed next to the module inside the protective structure. The residential module is connected to the airlock chamber (13), mounted from the spacecraft hulls. Emergency exit of astronauts from the space station in spacesuits is carried out through the emergency hatch (8), located opposite the emergency hatch at the end of the residential module.

Protection of the station's inhabitants from cosmic radiation, according to the latest data [22], is achieved by filling the BZS frame with a regolith layer of at least 0.76 m, and protection from the total radiation and seismic shock effects of meteorites weighing 1-100 g is achieved by filling with a regolith layer (2) up to 3 m thick. In each case, the thickness of the protective layer of regolith mainly depends on the meteorite hazard in the area of the station construction. To prevent the penetration of meteorites into the regolith protective layer of the BZS, a solid coating of regolith melt (1) with a thickness of at least 0.1 m is formed on its surface with the help of a solar concentrator

. 2.2.2 Method of erecting a frame-backfill structure of the BZS of a temporary habitable station

It is planned to use mobile robotic installations equipped with a dump and a universal manipulator with a bucket for collecting regolith and filling the frame of the BZS with it, which were proposed in the report [13].

The basic design of the BZS temporary station and a new type of this design on the Moon make it possible to build on their basis more complex structures of temporary and permanent stations containing various infrastructure modules – residential, research, storage, etc. and their combinations, the appearance of which is shown in Fig. 3.

Fig. 3. Complex structures of temporary and permanent habitable stations on the Moon based on the basic and new type of structures of BZS:

1 – BZS for residential modules;

2- anti-meteorite and anti-radiation layer of regolith and regolith blocks;

3- BZS stations for scientific and warehouse modules

One of the features of the frame-backfill BZS is the possibility of disassembling them if necessary and moving them to another part of the Moon, which will save significant financial resources and resources [19].

conclusion

The basic design of the BZS and a method for constructing a temporary habitable station on the Moon, erected in various ways using regolith, have been developed.

An application has been filed for invention No. 2022116899 for the basic design and method of erecting a manned station on the Moon.

Based on the basic design of the BZS, a new type of protective structure of a temporary habitable station on the surface of the Moon has been developed on the basis of a frame-filled formwork filled with regolith that does not require any special preparation.

The designs of folding SE frame-backfill BZS of a temporary inhabited station have been developed.

A successful experimental assessment of the possibility of increasing the radiosecurity of the BZS frame due to the use of radiosecured frame SE has been carried out.

For the first time, the possibility of accelerating the process of obtaining a barium-containing composite in a microwave oven has been experimentally shown.

The developed designs of the BZS of inhabited stations are proposed for use on space objects covered with regolith with a similar composition to the lunar one.

On the topic of research, 2 articles were published in journals from the list of the Higher Attestation Commission, 6 abstracts, 1 patent for an invention, 6 diplomas and 1 letter of thanks were received (Appendix P (1P, 2P, 3P, 4P, 5P, 6P).

LIST OF SOURCES USED

1. Shevchenko V.V. Lunar base. - M.: Znanie, 1991. - 64 p.

2. Grushinsky N.P., Dralkin A.G. Antarctica. -Moscow: Nedra, 1988. - 199 p.

3. Geophysical Research Letters. [electronic resource]. URL: https://doi.org/10.1029/2018GL078133 (accessed 05.10.2022).

4. Maximov A. To the South Pole // Radio. -1960.- No. 6. - pp. 16-17.

5. The Federal Space Program of Russia for 2016-2025. [electronic resource]. URL: http://www.promweekly.ru/2016-13-12.php #:~:text=% (accessed 13.11.2022).

6. The Russian Academy of Sciences stated ... [Electronic resource]. URL: https://tass.ru/kosmos/12469389. The Russian Academy of Sciences stated that the return of the lunar program is a priority of the Russian Federation in space exploration. TASS (09/21/2021) (accessed: 11/20/2021).

7. The moon is a step towards technologies for the development of the Solar system // Under the scientific editorship of Legostaev V.P. and Lopota V.A. M.: RSC Energia. - 2011. - 584 p.

8. TASS. Russian habitable base. [electronic resource]. URL: https://tass.ru/kosmos/5613596 (accessed: 20.10. 2022).

9. Barmin I.V., Egorov A.V. Unrealized space projects // Conversion and mechanical engineering. - 2001. - No. 2. - S. - 16-21.

10. Merzhanov A.I. Lunar base "Barmingrad". A project ahead of its time // The aerospace sphere. - 2018. - №2 (95). - Pp. 108-117.

11. Leonov V.A. Permanent lunar station as a priority of Russia in the development of space resources // The aerospace sphere. - 2021. - No. 4. - pp.

56-67. 12. Bugrov V. Tsiolkovsky and Korolev: dreams and reality // Science and Life. - 2007. - No. 9. - pp. 30-32.

13. Leonov V.A., Bagrov A.V., Galeev S.A., Malaya E.V., Nechaev A.L. The concept of construction of prefabricated shelters on the Moon // Materials of the 54th Scientific Readings in memory of K.E. Tsiolkovsky. - 2019. - pp. 225-228.

14. Leonov V.A. The concept of building a permanent lunar station // Collection of theses XLV Academic readings on cosmonautics. - 2021. Moscow: Bauman Moscow State Technical University. - T 2. - pp. 214-216.

15. Venglovskaya E.N. Architectural module on the Moon // Collection of theses XLV Academic readings on cosmonautics. - 2021. Moscow: Bauman Moscow State Technical University. - T 2. - pp. 210-211.

16. Bagrov A.V., Nesterin I.M., Pichkhadze K.M., Sysoev V.K., Sysoev A.K., Yudin A.D. Analysis of methods of construction of structures of lunar stations // Vestnik NPO named after S.A. Lavochkin. - 2014. - No. 4. - pp. 75-80.

17. Lunar soil: properties and analogues. Model of 1974. K.P. Florensky, A.T. Bazilevsky, O.V. Nikolaeva (compilers). – Moscow: Academy of Sciences of the USSR GEOHI named after V.I. Vernadsky. 1975.- 50 p.

18. Pyzhov A.M., Yanov I.V., Lukashova N.V., Shirokov I.Z., Lukonin A.A. Erecting and protecting a habitable station on the surface of the Moon // Butlerov Communications. - 2018. - Vol. 53. - No. 3. - pp. 112-119.

19. Pyzhov A.M., Leonov V.A., Yanov I.V. Generalized concept of prefabricated protective structures of habitable stations on the surface of the Moon and other natural space objects covered with regolith // Materials of the 57th Scientific readings in memory of K.E. Tsiolkovsky. – 2022. - H 2. – pp. 97-99.

20. Publications "Horizon 2100, 21" [Electronic resource]. URL: http://www.futurible.space/ru/winners/?season=3&category=10 (accessed 21.11.2022).

21. Pyzhov A.M., Leonov V.A., Yanov I.V. The concept of pre-erected protective structures of inhabited stations on non-atmospheric objects covered with regolith // Materials of the 56th Scientific readings in memory of K.E. Tsiolkovsky. - 2021.-Part 2.- pp.113-115.

22. After measuring radiation on the Moon, scientists proposed build a base under its surface (September 30, 2020). [electronic resource]. URL: https://habr.com/ru/news/t/521392 / (date of application: 05.11.2022).

23. Method of construction of pointed dome structures: RF Patent No. 2694455 / Yanov I.V., Pyzhov A.M., Poilov V.V., Lukashova N.V., publ. 15.07.2019. Byull. No. 20.

24. Treshnikov A.F. My polar travels. - M.: Mysl, 1985.- 476 p.

25. Handbook of the construction master. Edited by K.M. Novitchenko. - M.: Stroyizdat. 1958. – 694 p.

26. The company "Wooden house". [electronic resource]. URL:

https://sk-derevodom.ru/project/sbornyie / (accessed 09.11.2022).

27. Frame-filling technology. [electronic resource]. URL: https://travelerscoffee.ru/seedlings/karkasno-zasypnaya-tehnologiya-kak-postroit-karkasnyi-dom / (accessed 09.11.2022).

28. Locking connection. [electronic resource]. URL: https://www.kupitlaminat.ru/article/zamkovoe_soedinenie (accessed 09.11.2022).

29. Komarov G.V. Methods of joining parts from plastic masses. – M.: Chemistry, 1979. - 288 p.

30. Malakhovsky S.S., Panafidnikova A.N., Kostromina N.V., Osipchik V.S. Carbon fiber plastics in the modern world, their properties and applications // Advances in chemistry and chemical technology. - 2019. - Vol. XXXIII. - No. 6. - pp. 62-64.

31. Grishina A.N. Liquid glass building materials for special purposes: monograph / A.N. Grishina, E.V. Korolev; Ministry of Education and Science of the Russian Federation. - Moscow: MGSU, 2015. - 224 p.

32. Matveev M.A. On the structure of liquid glasses // Journal of the D.I. Mendeleev VHO. - 1963. - Vol. VIII. - No. 2. - pp. 205-210.

33. Poisoning with soluble barium salts. [electronic resource]. URL: https://www.sechenov.ru/pressroom/publications/otravlenie-rastvorimymi-solyami-bariya1 / (accessed 09.11.2022).

34. Zhapparbergenov R.U., Atabaev M.K., Doskeev Zh.M., Appazov N.O. Activation of synthesis of n-pentylbutanoate by microwave irradiation // Successes of modern natural science. – 2016. – No. 3. – pp. 29-32.

35. Petrov E.M., Yunusova L.M. et al. The effect of microwave radiation in chemical reactions // Bulletin of Kazan Technological University. - 2015. - Vol. 18. - No. 3. - pp. 28-32.

36. Budnikov P.P. Inorganic materials. - M.: Nauka, 1968.-420 p.

37. Veialkina N.N., Borbotko E.P., Aksenenko O.S., Polevich V.V., Medvedeva E.A. Comparison of biological efficiency of gamma and X-ray radiation in vivo // Proceedings of the 22nd International Conference "Sakharov Readings 2022: environmental problems of the XXI century". - 2022. – Part 1. - pp. 293-296.

38. Barite plaster. [electronic resource]. URL: https://fasad-exp.ru/vidy-materialov-dlya-otdelki-fasadov/shtukaturka/baritovaya-shtukaturka.html (accessed 12.09.2022).

39. Knauf-Safeboard Plate. [electronic resource]. URL: https://www.knauf.ru/catalog/find-products-and-systems/knauf-sejfbord.html (accessed 10.11.2022).